Current vacancies available in Denmark. | Aktuelle ledige stillinger i Danmark.

Since 2013, we have served as a key partner to Harbour Energy, evolving our support into a full suite of services. We deliver comprehensive asset integrity solutions for their North Sea operations.

Client

Location

HSEQ

During recent shutdown campaigns on our client’s Everest and Lomond installations, our integrated approach combined, Access, Cleaning, and Inspection expertise. Our Inspection and Non‑Destructive Testing (NDT) teams worked in close collaboration with Cleaning and Mechanical crews to guarantee that every shutdown was executed with the highest standards of safety, efficiency, and technical precision in mind.

Our Inspection and NDT teams provided full campaign support across Harbour Energy’s critical process systems, including dense phase, gas, and vent coolers. We applied a tailored combination of inspection methods to suit each exchanger’s unique design and condition. One notable challenge arose during an Internal Rotary Inspection System (IRIS) inspection of fuel gas heaters, where we were faced with a significant access constraints.

On the North Everest platform, the design of the heat exchanger allowed for efficient inspection access. The connecting pipework was bolted both at the tube sheet and along the pipeline, enabling straightforward disassembly. This configuration allowed our teams to easily remove the pipework and access the internal components of the exchanger without the need for any additional requirements.

In contrast, the Lomond platform presented a more complex challenge. While the tube sheet connection was similarly bolted, the adjoining pipework was fully welded. This limited direct access to the heat exchanger and left minimal clearance to manoeuvre the internal tube bundle.

The operation demanded precise planning, specialist tooling, and strict adherence to safety protocols to ensure the exchanger could be accessed, inspected and re-assembled safely within the shutdown window.

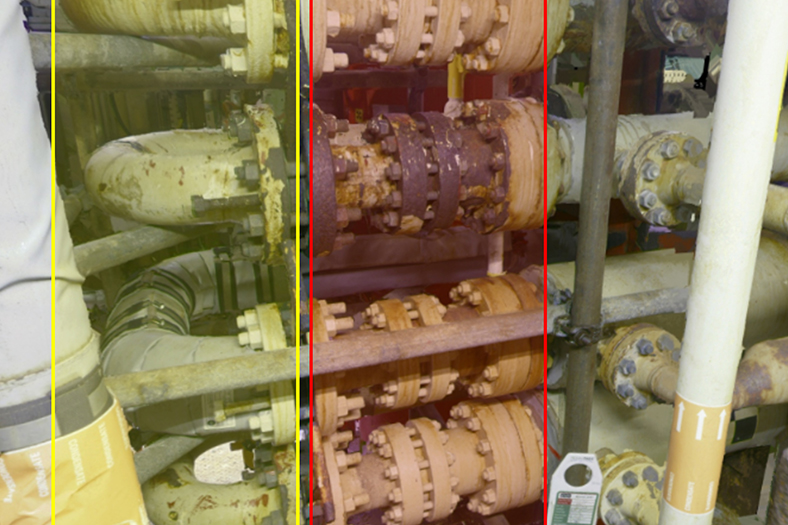

Photo: Bolted connection to the heat exchanger tubesheet.

Working closely with our Mechanical crew, the team devised an on-site solution that involved modifying their equipment. They removed the bolts on one side and carefully repositioned the pipework to maximise clearance without placing undue stress on the welded connection, achieving approximately an additional 0.3 metres of space.

The IRIS probe assembly was then cut to the required length and the connections rethreaded, enabling the full assembly to function effectively within the confined space. This adaptation allowed for a successful and accurate inspection without compromising the integrity of the surrounding pipework.

Photo: Modified IRIS centraliser, allowing access to the tube sheet.

Through effective communication and collaborative problem-solving, we successfully adapted our equipment to meet the unique access constraints, without compromising its integrity or fitness for purpose. This quick response and innovative thinking enabled us to complete the inspection safely, on time, and to the highest technical standards, reinforcing our commitment to operational excellence even in challenging situations.

Having the right equipment, techniques, and technical knowledge is critical, not only to deliver accurate inspection results, but also to give our clients confidence that their assets remain safe, compliant, and operating at peak efficiency. By combining innovation with experience, we ensure that every inspection adds value, supports informed decision-making, and contributes to the long-term integrity of critical infrastructure.

Through our partnership approach, we deliver comprehensive support and a complete range of inspection and Non‑Destructive Testing (NDT) services during every stage of an asset’s lifetime – from fabrication through to decommissioning.

We focus on utilising innovative techniques that meet the evolving needs of our clients. Our team of level 3 qualified technical experts explore new ideas and transform them into operational solutions.