Current vacancies available in Denmark. | Aktuelle ledige stillinger i Danmark.

An agricultural chemical manufacturer awarded Altrad their integrated asset integrity management services contract in 2021.

Client

Location

HSEQ

Non-Intrusive Inspection (NII) of pressure vessels and pipework eliminates the need for plant shutdowns and high-risk confined space entries, required by traditional internal visual inspections (IVI).

Utilising advanced non-destructive testing (NDT) technologies, NII offers comprehensive inspection coverage, ensuring safe and reliable operations without costly and time-consuming shutdowns.

By integrating robust risk-based assessments, NII provides detailed data for fitness-for-service evaluations and tracks degradation rates.

Photo: Chlorine storage tank

An agricultural chemical manufacturer awarded Altrad their integrated asset integrity management services contract in 2021.

As part of this, the client requested Altrad to carry out a full NII on a chlorine storage tank at their chemical plant.

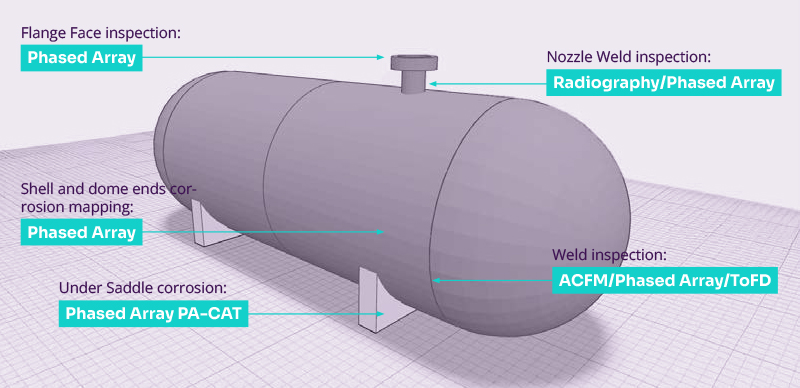

Photo: Damaged mechanisms & inspection strategies

As part of the Non-Intrusive Inspection (NII) strategy, inspection areas were carefully selected based on our vessel inspectors’ in-depth knowledge of the tank system, its operational history, and the degradation mechanisms most likely to occur. The inspection plan focused on high‑risk areas and known points of susceptibility, ensuring the most appropriate techniques were applied where they would provide the greatest value.

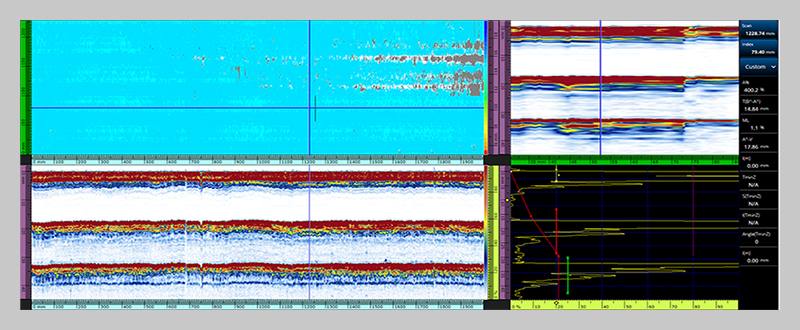

Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction (TOFD) were used to assess internal wall loss across the vessel shell and welds, enabling accurate detection of corrosion and weld defects. PAUT provided high-resolution corrosion mapping, allowing areas of reduced wall thickness to be identified and monitored over time, supporting long‑term integrity management and asset life planning.

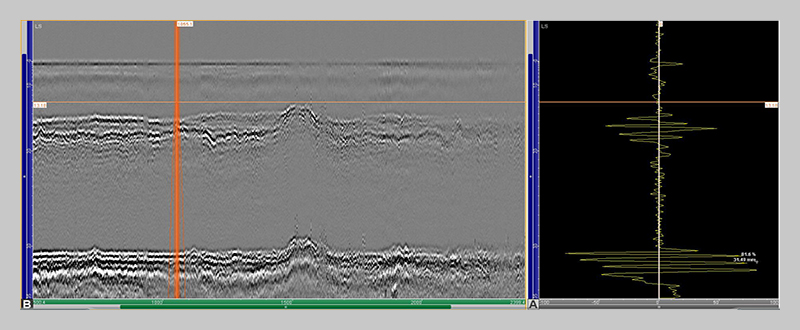

TOFD is a tried and tested method for weld inspections, particularly when assessing root and weld erosion/corrosion. Using probes positioned either side of the weld, TOFD provides full through-wall coverage, allowing for more accurate detection of root erosion and manufacturing defects.

ACFM (Alternating Current Field Measurement) was also deployed – a clean, efficient, and environmentally friendly surface inspection method capable of detecting and sizing surface-breaking defects on external vessel surfaces without the need for surface preparation or consumables.

In addition, PAUT or radiography were employed for flange face corrosion inspection and complex nozzle weld geometries, where standard ultrasonic scanning techniques can be less effective.

Photo: Example of wall thickness data

Photo: Example of ToFD data

With our partnership approach, we deliver comprehensive support and a complete range of inspection and NDT services during every stage of an asset’s lifetime – from fabrication through to decommissioning.

We focus on utilising innovative techniques that meet the evolving needs of our customers. Our team of level 3 qualified technical experts explore new ideas and transform them into operational solutions.